Introduction

Semi-solid batteries are increasingly promoted as the next evolution in lithium battery technology.

Higher safety.

Higher energy density.

Longer cycle life.

But when applied to consumer electronics — especially wireless power banks — do semi-solid cells represent a real engineering upgrade, or simply a marketing narrative?

This article examines the technical reality behind semi-solid battery adoption in portable power devices.

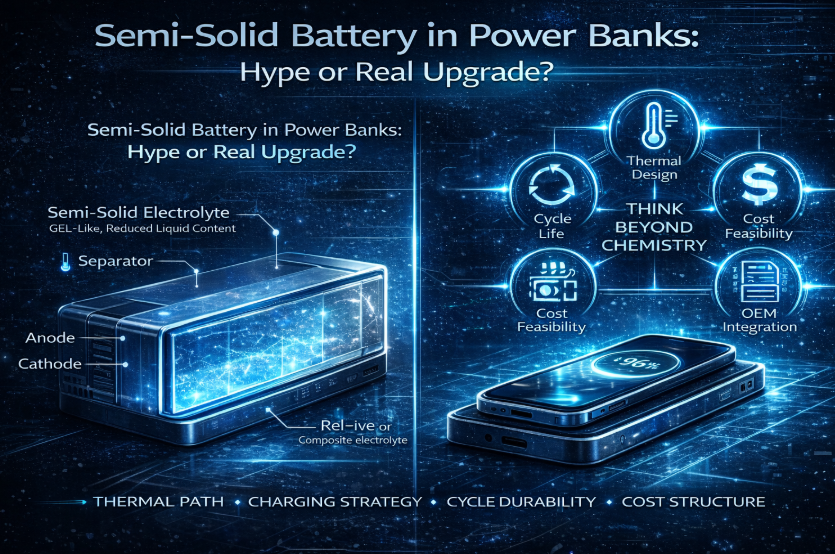

What Changes in a Semi-Solid Battery?

Traditional lithium-ion cells use liquid electrolytes.

Solid-state batteries replace them with fully solid electrolytes.

Semi-solid batteries sit between these two extremes:

- Reduced liquid electrolyte content

- Gel-like or composite electrolyte systems

- Modified separator and cathode structures

The goal is to improve stability without completely redesigning manufacturing infrastructure.

This hybrid approach makes semi-solid more commercially accessible than full solid-state.

Claimed Advantages in Consumer Devices

Manufacturers typically highlight:

- Improved thermal stability

- Reduced leakage risk

- Higher energy density

- Enhanced structural robustness

However, performance depends heavily on system integration, not just cell chemistry.

In portable power banks, the real question is:

How does semi-solid behave under wireless charging heat and compact mechanical constraints?

Thermal Stability — Material vs System

Semi-solid electrolytes can offer better resistance to thermal runaway propagation.

But wireless power banks generate heat from:

- Inductive charging inefficiency

- Continuous magnetic attachment

- High state-of-charge top-up behavior

If system-level thermal path design remains unchanged,

cell-level improvements may not fully translate into device-level reliability.

Thermal management still determines real-world performance.

Energy Density vs Safety Trade-offs

Higher energy density often increases:

- Thermal sensitivity

- Structural stress

- Manufacturing complexity

Semi-solid cells may allow moderate density gains without extreme volatility,

but safety margins remain dependent on:

- BMS strategy

- Charging profile

- Mechanical compression design

Energy density gains do not automatically equal safer products.

Cycle Life Reality

Marketing claims often highlight extended cycle life.

However, real-world aging in power banks is influenced by:

- High SOC exposure

- Elevated internal temperature

- Continuous attachment behavior

- Irregular charging patterns

Without optimized charging control and thermal path integration,

semi-solid chemistry alone will not prevent degradation.

Cost & Supply Chain Constraints

Semi-solid batteries:

- Require modified production lines

- Have limited large-scale consumer electronics adoption

- Currently carry cost premiums

For OEMs, adoption must balance:

- Brand positioning

- Target market sensitivity

- Product price tier

Technology readiness does not always align with commercial feasibility.

When Does It Make Sense for Power Banks?

Semi-solid cells may be appropriate when:

- Targeting premium flagship products

- Thermal risk tolerance must be minimized

- Brand positioning emphasizes innovation

- Volume is moderate and margins allow flexibility

For entry-level or cost-driven SKUs,

conventional high-quality lithium-ion may remain more rational.

Conclusion

Semi-solid battery technology is neither pure hype nor automatic upgrade.

It is a material-level advancement that must be evaluated through:

- System thermal design

- Charging strategy

- Mechanical structure

- Cost structure

Only when integrated thoughtfully into the full product system

does it become a meaningful innovation.