Why I’m Writing This (A Real Question I Hear Every Week)

I’ve been working with power banks and battery packs for years, and I still hear the same question again and again:

“Why does my 10,000mAh power bank only charge my phone about two times?”

Honestly, this confusion is not stupid at all.

I hear it not only from consumers, but also from product managers, buyers, and even brand founders.

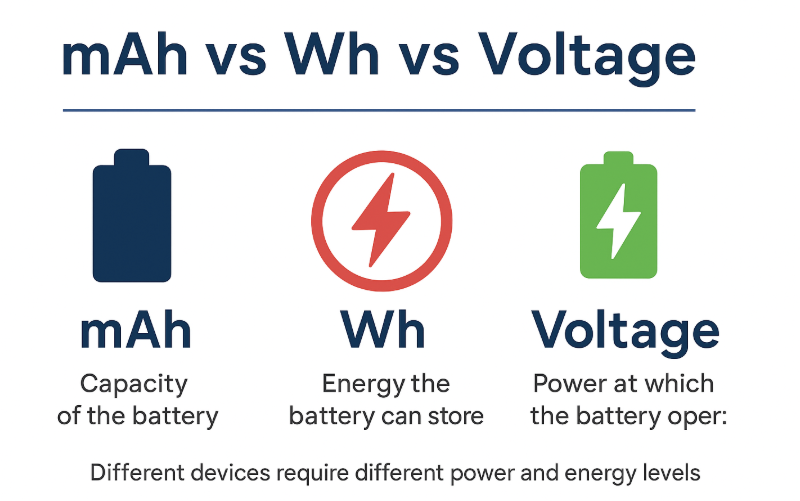

Capacity, energy, voltage, fast charging, efficiency — they are often mixed together.

So in this article, I want to explain — from real factory and testing experience — how:

- Battery series vs parallel works

- Why mAh is not equal to real charging times

- How fast charging changes battery stress

- And why battery C-rate is one of the most overlooked risk factors in modern power banks

No complicated theory. Just logic that actually matches real products.

Series vs Parallel — The Simplest Explanation

Let’s start with a mental picture.

🔋 Batteries in Parallel

- Voltage stays the same

- Capacity (mAh) adds up

Example

Two 3.7V 5,000mAh cells in parallel →

3.7V / 10,000mAh

This is the most common structure in standard phone-focused power banks.

🔋 Batteries in Series

- Voltage adds up

- Capacity stays the same

Example

Two 3.7V 5,000mAh cells in series →

7.4V / 5,000mAh

This design is often used when higher voltage or higher power output is required — especially for tablets and laptops.

Capacity vs Energy: Where Most People Get It Wrong

Here’s the key truth I always explain to customers:

mAh is not the full story. Energy (Wh) is.

What “Capacity” (mAh) Really Means

When a power bank is labeled 10,000mAh, that number is based on the battery cell’s nominal voltage, usually 3.6–3.7V.

So the real stored energy is:

Energy (Wh) = Capacity (Ah) × Voltage (V)

Example

10,000mAh × 3.7V ≈ 37Wh

Why Your Phone Doesn’t Care About 3.7V

Your phone does not charge at 3.7V.

Typical charging voltages:

- 5V (standard charging)

- 9V / 12V (fast charging phones)

- 15V / 20V (tablets & laptops)

So the power bank must boost voltage, and that conversion is never 100% efficient.

Where Energy Is Lost: Voltage Conversion Explained

In real testing, what I usually see:

- 85–92% efficiency in well-designed power banks

- Below 80% in cheap or poorly optimized ones

So that 37Wh becomes roughly:

👉 30–33Wh usable output

That’s why:

A “10,000mAh” power bank usually charges a

12–13Wh phone battery about 2 times, not 3.

This is normal physics — not cheating.

Fast Charging Voltage Steps (5V / 9V / 15V / 20V)

Fast charging isn’t magic. It’s voltage negotiation.

| Device Type | Typical Voltage |

|---|---|

| Earphones / accessories | 5V |

| Fast-charge phones | 9V |

| Tablets | 9V / 12V |

| Laptops | 15V / 20V |

To support 20V output, a power bank must either:

- Use series battery design, or

- Use very high-current boost conversion

Both choices affect cost, size, thermal design, and safety margin.

Why Series Design Matters for Laptops (Real ODM Experience)

From real projects I’ve worked on:

- Parallel-only designs struggle above 45W

- Series configurations reduce current stress

- Lower current = less heat = better reliability

That’s why many laptop power banks internally use:

👉 2S or even 3S battery structures

⚡ Why Battery C-Rate Matters (And Why Many Power Banks Fail Here)

This is the part most people never talk about, but it explains many recalls.

What Is Battery C-Rate?

C-rate describes how fast a battery can safely discharge relative to its capacity.

- 1C → full discharge in 1 hour

- 2C → full discharge in 30 minutes

- 3C → full discharge in 20 minutes

Higher output power + smaller capacity = higher required C-rate.

This is why normal charging, PD 20W, 45W, 100W, and 140W all demand completely different battery capabilities.

Battery Rate Calculation (Engineering Reality)

In real product design, we use this simplified formula:

Minimum Battery C-Rate =

Maximum Output Power

÷ Conversion Efficiency

÷ Minimum Battery Voltage (≈3V)

÷ Battery Capacity (Ah)

Example: Key Ring Power Bank

If a key ring power bank outputs 10W:

10W ÷ 80% ÷ 3V ÷ 2Ah = 2.08C

If it outputs 15W:

15W ÷ 80% ÷ 3V ÷ 2Ah = 3.125C

That’s an extremely demanding requirement for such a small battery.

Typical Market Examples

| Product Type | Capacity | Output | Required C-Rate |

|---|---|---|---|

| Standard power bank | 10,000mAh | PD 20W | ~1C |

| Magnetic power bank | 5,000mAh | PD 20W | ~1.7C |

| Key ring / mini bank | 2,000mAh | 10–15W | 2–3C+ |

This is why phone batteries usually have higher C-rates — smartphones are designed for high current, tight thermal control, and advanced materials.

Why High C-Rate = Higher Risk

From factory audits and recall analysis I’ve seen:

Most magnetic power bank recalls are C-rate problems, not capacity problems.

Excessive battery rate can cause:

- Overheating

- Accelerated aging

- Swelling

- Internal short circuits

- In extreme cases, fire incidents

Battery C-rate is closely tied to:

- Cell chemistry & materials

- Manufacturing consistency

- Internal resistance control

- Quality inspection & aging process

Recommended C-Rate for Portable Power Banks

Based on real engineering and certification experience:

1C–2C is the safest range for most portable power banks.

- Good power output

- Better thermal margin

- Longer cycle life

- Easier UL / CB / IEC approval

⚠ Above 2C must be handled with extreme care, including thermal design, structure, and material selection.

Safety & Certification: Series, Parallel & C-Rate All Matter

From a compliance perspective:

- Series packs face stricter over-voltage and balancing checks

- High C-rate designs face tougher thermal and abnormal condition tests

Certifications affected include:

- IEC 62133 / CB

- UL 2056 / UL 62368

- KC / PSE / CCC

Design choice directly impacts time-to-market, not just performance.

Series or Parallel — Which One Is Better?

👉 Neither is “better” universally.

| Use Case | Better Choice |

|---|---|

| Phone-only power bank | Series |

| Slim & lightweight design | Series+ Parallel |

| Laptop & tablet support | Series |

| High-power PD (45W+) | Series+ Parallel |

| Cost-sensitive projects | Parallel |

Final Takeaways (Remember These 3 Things)

- mAh ≠ real charging times — Wh matters more

- Fast charging increases battery stress — C-rate matters

- Series vs parallel is a strategy, not a quality label

If you understand these three points, you already know more than most buyers.

About the Author

Written by an OEM/ODM Power Bank Engineer at Reachinno

I’ve spent over 10 years working inside power bank factories — from early prototype design to mass production for EU, US, and AU retail brands.

I’ve personally worked on series, parallel, and hybrid battery pack designs, handled UL / CB / CCC / KC certifications, and dealt with real-world issues like swelling, thermal shutdowns, and fast-charging failures.

This article is not theory-only.

Everything here comes from what I’ve tested, failed, fixed, and shipped.

👉 You can connect with me on LinkedIn, where I share engineering insights about battery safety, fast charging, and power bank design.