Why I’m Writing This (Straight from the Trenches)

I’ve been knee-deep in lithium-ion batteries and power banks for more than 10 years—handling everything from sketchy prototypes to full-scale production runs for big retail brands in the EU, US, and Australia.

I’ve dealt with:

- Power banks that came back “just a little puffy” but bombed hard in safety retests.

- Magnetic chargers that got scorching hot during everyday phone top-ups.

- Packs that aced electrical checks but melted down in thermal stress tests.

The kicker? Over 90% of these flops weren’t from dumb user errors—they were straight-up design flaws where margins were too tight. This guide cuts through the fluff to explain why batteries fail, based on real factory audits, certification headaches, accident breakdowns, and the latest data from sources like NREL’s Battery Failure Databank. No textbook theory; just hard lessons from the production line, backed by stats and visuals.

1. Breaking Down Swelling, Leakage, and Fires: What They Really Signal

In simple terms: These are red flags for chemical chaos or structural breakdowns inside the cell.

Every lithium-ion battery is a sealed chemical reactor. Lithium ions shuttle back and forth during charge and discharge, but if things go sideways:

- Abnormal reactions spit out gases (like CO₂ or hydrocarbons).

- Heat builds up unchecked.

- Internal shorts spark disaster.

When pressure hits critical:

- Pouch cells balloon out.

- Cylindrical ones bulge at the caps.

- Seals crack, leading to leaks.

- Uncontrolled heat triggers thermal runaway—boom, fire.

Here’s a real-world example of what swelling looks like in a lithium-ion battery:

How to Deal with Swollen Lithium Battery and All things You …

Lithium Battery Disposal: Swelling and Fire Hazards …

2. The Real Culprit Behind Swelling: Electrolyte Breakdown

Swelling is the most frequent headache, and it boils down to electrolyte decomposition. This happens when:

- You overcharge the battery (pushing voltage too high).

- It runs hot for too long.

- Discharge rates (C-rate) spike beyond what the cell was built for.

- The solid electrolyte interphase (SEI) layer gets worn out from repeated deep cycles.

These triggers kick off side reactions that churn out gases. With no escape route in a sealed cell, pressure mounts, and the battery puffs up like a bad airbag. Data shows lithium batteries can swell with a thickness growth rate of 6% to 20% after high-temperature storage or cycling.

High-energy cathodes amp up the danger. Stuff like nickel-rich NCM or NCA packs more punch per cubic inch but:

- They’re chemically twitchy.

- They lose stability faster than safer options like LFP (lithium iron phosphate).

Engineering truth bomb: Chasing max energy density always eats into your safety buffer. You have to beef up designs to compensate—or pay the price later.

3. Overcharge and Over-Discharge: Silent Killers That Speed Up Failures

Overcharge: From Lattice Cracks to Full Meltdown

Push voltage past the limit, and here’s the chain reaction:

| Stage | Internal Effect |

|---|---|

| Voltage spikes | Cathode structure cracks, lithium plates as metal dendrites. |

| Dendrites grow | They poke through the separator, creating shorts. |

| Side reactions ramp up | Heat and gases explode in volume. |

| Endgame | Swelling escalates to thermal runaway and fire. |

A faulty battery management system (BMS) turns this into a nightmare—it’s often deadlier than a bad cell alone.

Over-Discharge: The Slow Burn

Drain it too low, and:

- The SEI layer crumbles.

- Copper from the current collectors dissolves, hiking internal resistance.

- Recharging sparks violent reactions.

I’ve seen swelling pop up weeks after a single deep discharge. It’s not immediate, but it’s inevitable if ignored. For context, over-discharge contributes to many of the 25,000+ lithium-ion fire incidents reported in the US from 2017-2022.

4. Heat and Everyday Environments: Not Just “Extreme” Conditions

Batteries don’t need a furnace to fail—regular use can cook them.

| Temperature | What Goes Wrong |

|---|---|

| 40°C (104°F) | Side reactions pick up speed, degrading components faster. |

| 60°C (140°F) | SEI layer breaks down quickly, exposing raw materials. |

| 80°C+ (176°F) | Thermal runaway becomes a real threat. |

Magnetic power banks are prime suspects here:

- They stick right to your phone, trapping heat.

- No airflow means poor cooling.

- Constant quick charges cycle them hard.

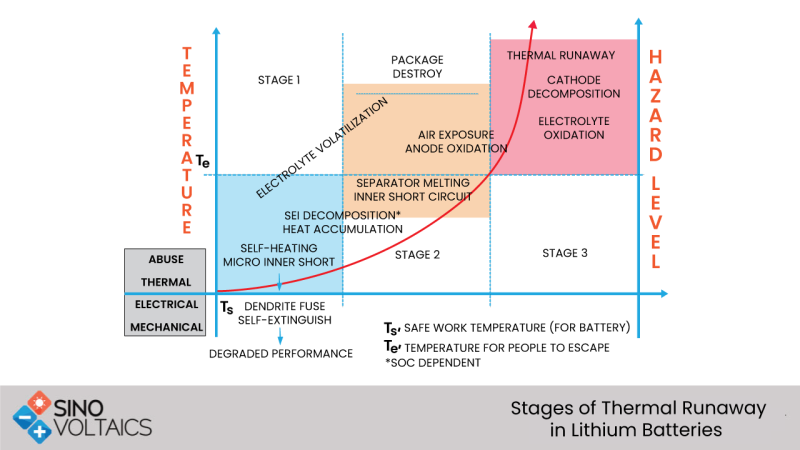

This isn’t user error; it’s a core design flaw in compact gadgets. During thermal runaway, temperatures can spike from 200°C to 1,000°C. Check this graph showing the stages of thermal runaway in lithium batteries:

Stages of The Thermal Runaway Process in Lithium Batteries

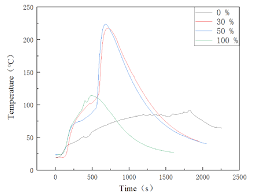

And here’s a temperature curve for NMC Li-ion batteries during runaway:

Thermal runaway temperature curve of NMC Li-ion batteries As shown …

5. Internal Short Circuits: The Fast Track to Catastrophe

Shorts are the scariest because they’re invisible until it’s too late. Common culprits:

| Risk Source | Typical Trigger |

|---|---|

| Raw materials | Metal impurities sneaking in. |

| Winding process | Electrodes misaligned during assembly. |

| Separator issues | Too thin or flawed material. |

| Welding | Splatter from poor joins. |

| Factory cleanliness | Dust or particles contaminating cells. |

Once a short forms:

- Heat explodes in a tiny spot.

- Electrolyte boils and vaporizes, jacking up pressure.

- Separator melts or shrinks, widening the short.

- Flammable guts ignite.

- Venting, fire, or explosion follows.

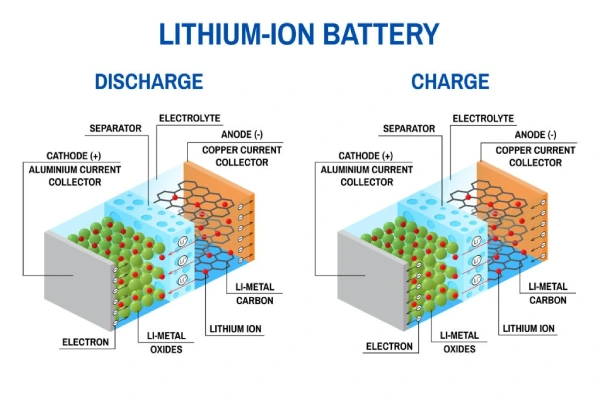

Fires feel “random,” but the seeds were planted during manufacturing. Visualize it with this diagram of a lithium-ion battery’s internal structure:

Why Do Lithium Batteries Short Circuit and How to Avoid?

And a simple short circuit principle illustration:

Why Do Lithium Batteries Short Circuit and How to Avoid?

6. Should You Keep Using a Swollen or Leaky Battery? Hell No.

Straight from experience: Don’t even think about it.

Swelling or leaks mean:

- The cell’s structure is shot.

- Shorts are way more likely.

- Leaked electrolyte is nasty—corrosive and toxic.

Never Do This:

- Poke or squeeze it.

- Heat it up.

- Tear it apart.

Do This Instead:

- Pull the plug right away.

- Stash it in a cool, ventilated spot away from flammables.

- Haul it to a certified recycler—no trash bin heroes.

Ignoring this is playing Russian roulette with your safety.

7. Why Battery Mishaps Are Spiking Lately

Batteries aren’t getting crappier; demands are just ramping up:

- Energy density is skyrocketing for slimmer devices.

- Products are shrinking, leaving less room for cooling.

- Fast charging pushes higher power through tiny cells.

- C-rates are climbing to meet “quick boost” expectations.

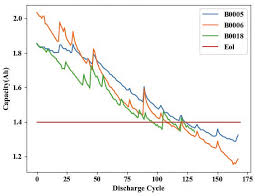

Magnetic power banks? They hit all these pain points at once. From what I’ve seen in recent audits, incident reports are up—in 2022 alone, over 333 facility fires in the U.S. and Canada were linked to lithium-ion failures, resulting in 48 injuries and 5 fatalities. Here’s a chart on battery capacity and failure thresholds:

Capacity and failure threshold of lithium-ion batteries …

And another on lithium-ion battery failure hazards:

A Review of Lithium-Ion Battery Failure Hazards: Test Standards …

8. Real-World Tips: From Factory Floors to Your Pocket

For Everyday Users

- Skip hot storage spots (like car dashes in summer).

- Ditch any swollen gear ASAP.

- Don’t obsess over “ultra-slim” or “super-fast”—balance with safety.

For Brands, Buyers, and B2B Pros

- Look beyond mAh ratings; grill suppliers on C-rate limits, thermal headroom, and cert margins.

- For magnetic designs, force derating—cut power output to build in buffers.

- Demand full abuse testing data, not just basic certs.

In production, I’ve pushed for these tweaks and seen failure rates drop by half.

Featured Snippet Summary

Lithium-ion batteries swell, leak, or catch fire from chemical instabilities like electrolyte decomposition, overcharge, high heat, or internal shorts. Key causes include manufacturing defects and high C-rates. Stop using damaged batteries immediately and recycle them safely to avoid risks.

FAQs for User Engagement

What causes lithium battery swelling most often?

– Electrolyte breakdown from overcharge, heat, or high discharge rates generates trapped gases. Data indicates 6-20% thickness growth from high-temp exposure.

Can a swollen battery explode?

-Yes, if ignored—it raises internal short risks leading to thermal runaway.

How to prevent lithium battery fires?

-Use quality chargers, avoid extreme temps, and monitor for swelling. For pros: Design with ample safety margins.

Are LFP batteries safer than NCM?

-Absolutely—lower reactivity means better thermal stability, though less energy density.

About the Author

Penned by an OEM/ODM Power Bank Engineer at Reachinno. With 10+ years validating lithium-ion packs for global markets, this draws from hands-on audits, failed certs, and real incident teardowns. Reach out on LinkedIn for B2B chats or custom advice—let’s build safer power solutions.