A Complete Guide to Quality, Safety, and Certifications Across Global Markets

Power bank quality control, power bank manufacturing process, power bank production flow, power bank certifications, UL 2056, CE certification, CB, PSE Japan, KC Korea, RCM Australia, MFi, Qi certification, OEM ODM power bank supplier.

For serious brands and distributors, a power bank is a lithium battery product that must be engineered for safety, consistency, and compliance – not treated as a cheap giveaway. Robust quality control is the only way to protect end users from swelling cells, fire risk, and dead‑on‑arrival units while protecting your margins and reputation.

Why Quality Control Matters More Than Ever

For serious brands and distributors, a power bank is not a basic accessory—it’s a high-energy lithium-ion device that can strengthen or destroy your brand overnight.

One swelling cell, one thermal runaway, or one defective batch can cause:

- Retailer chargebacks

- Customs seizure

- Store recalls

- Permanent damage to consumer trust

This is why Reachinno builds two parallel systems into every project:

- A complete manufacturing flow (Production Flow Chart)

- A 12-Step Quality Control Framework

Together, they ensure every power bank is safe, compliant, and retail-ready for markets including the U.S., EU, Japan, Korea, Australia, India, China, and more.

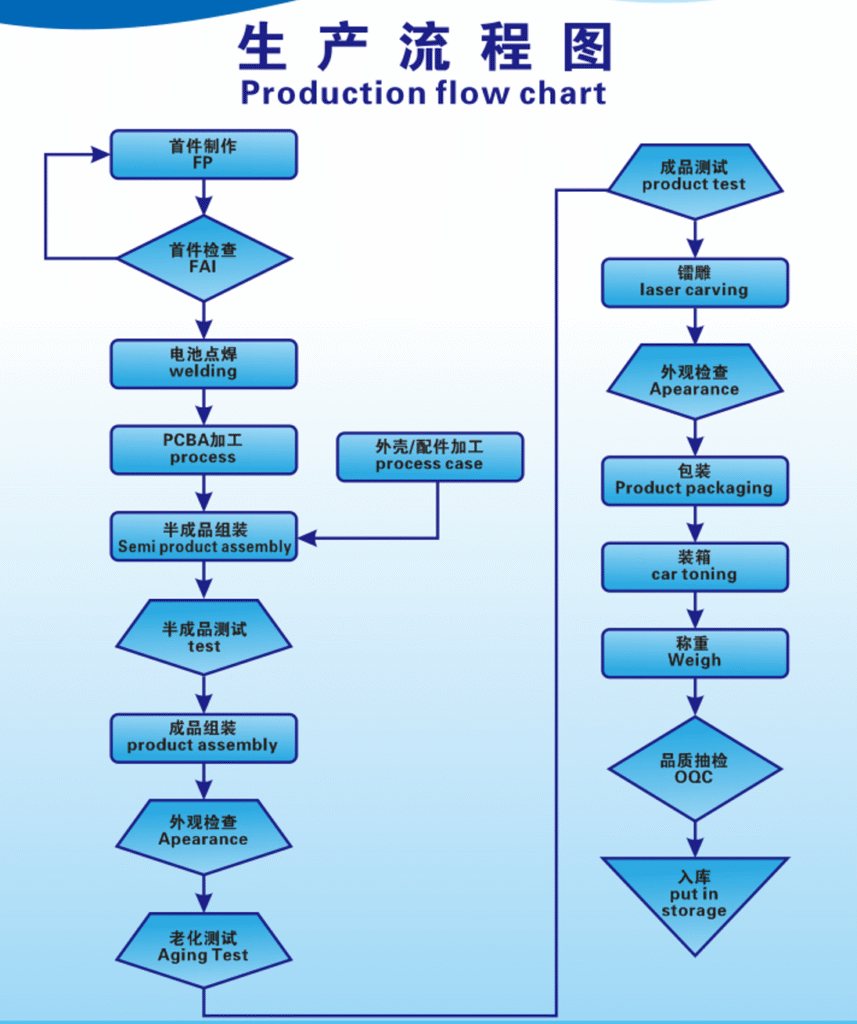

🔷 Production Flow Chart (Integrated Into QC System)

This flowchart visually shows how Reachinno manages:

- FP / FAI

- Cell welding

- PCBA processing

- Semi-assembly

- Final assembly

- Aging test

- Product test

- Laser engraving

- Packaging

- Cartoning

- OQC

- Storage

This production flow is the backbone of our manufacturing system, and the 12-Step QC Framework overlays on top of this process, ensuring each stage is monitored with measurable checkpoints.

🔷 The 12-Step QC System That Protects Your Brand

Step 1 — Supplier Qualification & Traceability

Before production starts, we validate every supplier for:

- Quality system capability

- Battery safety performance

- RoHS/REACH compliance

- Process stability

- Full traceability data

Every component batch is assigned a traceable ID—a requirement for UL, CCC, PSE, KC and top retailers.

Step 2 — IQC on Cells, PCBs, and Structural Parts

Incoming materials undergo:

- AQL sampling

- Appearance + dimension checks

- Internal resistance + capacity test for battery cells

- PCBA visual + functional check

- Housing/port tolerance test

Only approved materials enter production.

Step 3 — SMT & PCBA Process Control

Defects often originate in PCBA.

We control SMT using:

- SPI (solder paste inspection)

- AOI (automatic optical inspection)

- X-ray for BGA and hidden joints

- Controlled reflow temperature profiles

- ESD-protected areas

This ensures clean solder joints, stable PD protocols, and reliable fast charging.

Step 4 — Cell Matching & Grouping

Cells are matched by:

- Capacity

- Internal resistance

- Voltage curve

- Temperature behavior

Matched cells = better cycle life, lower heat, and lower swelling risk.

Step 5 — Mechanical Fit & Structural Verification

We check:

- Housing fit

- Port alignment

- Button and LED alignment

- Screw torque

- Snap-fit reliability

- Minor drop / torsion / insertion tests

This prevents misalignment, rattling, and cosmetic issues after shipping.

Step 6 — Controlled Assembly Line with Checkpoints

Assembly follows detailed SOPs with:

- Welding quality control

- Wire routing validation

- Port alignment

- Torque control of screws

- In-line functional testers for LEDs, buttons, and ports

This ensures structural and electrical stability.

Step 7 — Protection Circuit & Safety Validation

We simulate real-world misuse:

- Over-current

- Over-voltage

- Over-discharge

- Short-circuit

- Thermal protection

- Rapid plug/unplug

Protection must trigger at precise thresholds defined in UL 2056, IEC 62133, GB 31241, etc.

Step 8 — Electrical & Fast-Charging Performance Test

Dynamic testing includes:

- Voltage stability

- Ripple & noise

- Conversion efficiency

- PD / QC compatibility

- PPS handshake

- Multi-port load balance

Essential for premium USB-C PD models.

Step 9 — Environmental & Reliability Testing

Depending on the destination market, we conduct:

- High/low temperature

- Thermal cycling

- Vibration

- Impact

- Altitude simulation

- Battery crash tests

Mandatory for GB 31241, KC Korea, PSE Japan, and EU RED.

Step 10 — 100% Aging Test & Burn-in

Every batch undergoes:

- Charge/discharge cycles

- Thermal performance monitoring

- Load simulation

- Early-failure detection

Abnormal units are removed and reworked.

Step 11 — Final Inspection & Packaging QC (AQL)

We check:

- Surface & cosmetic quality

- Printing & logo position

- Port integrity

- Barcode accuracy

- Accessories

- Packaging compliance

- Carton drop test

Ensures products survive retail logistics.

Step 12 — Pre-Shipment Audit & Continuous Improvement

Before shipping:

- QC team / Third party (SGS, Intertek, TUV) inspection

- Random performance verification

- Aging data review

- Quantity & sealing check

- Full traceability documents

We integrate customer feedback to improve each new batch.

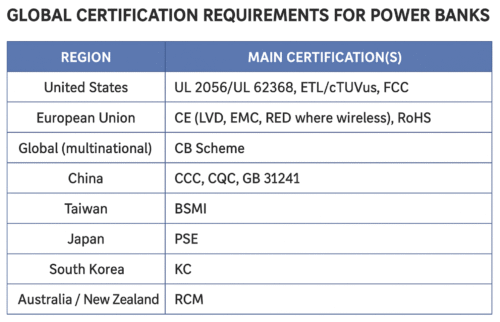

🌍 Power Bank Certification Requirements (By Region)

| Region | Certification | Focus |

|---|---|---|

| USA | UL 2056 / UL 62368 / FCC | Battery safety + EMC |

| EU | CE (LVD/EMC/RED) + RoHS | Safety + EMC + Radio |

| China | CCC / CQC + GB 31241 | Lithium battery pack safety |

| Japan | PSE | Electrical safety |

| Korea | KC | Safety + EMC |

| Taiwan | BSMI | Safety + EMC |

| Australia/NZ | RCM | Electrical safety + EMC |

| India | BIS + WPC | Safety + Wireless |

| Global | CB Scheme | IEC-based safety reports |

| Wireless products | WPC Qi / Qi2 | Wireless charging safety |

| Apple ecosystem | MFi | Lightning/MagSafe compliance |

Each certification requires specific sample prep, test plans, and documentation—Reachinno supports all.

What Top Brands Do Differently—and What We Apply

Leading brands such as Anker, Baseus, Belkin, ZMI, Energizer emphasize:

- Multi-layer battery protection

- High-standard PCB design

- Strong mechanical reliability

- Beautiful industrial design

- Clear certification & compliance labeling

Reachinno applies the same standards for OEM/ODM projects, ensuring premium quality at scale.

Why Reachinno Is a Safer OEM/ODM Partner

With our 12-step QC system + full certification coverage, we help you:

- Reduce defect rates

- Lower after-sales cost

- Avoid customs issues

- Pass retailer audits easily

- Launch simultaneously in multiple countries

- Build stronger brand trust

- Deliver safer, more competitive power banks

From concept → certification → mass production → shipment, Reachinno manages every detail.